FlexBotNDT – Flexible non-destructive testing using collaborative robots

Non-destructive materials testing (NDT) is an indispensable area of quality assurance.

Materials testing comprises various test methods used to determine the behavior and material characteristics of standardized material samples or finished components under mechanical, thermal, or chemical stresses. Material is tested, for example, with regard to its purity, freedom from defects, or load-bearing capacity.

The common test methods are divided into destructive and non-destructive material tests. With the aid of NDT, it is possible to make statements about the condition of materials without damaging them. This often involves anomalies, external features on castings and forgings, or the structure of base material. Therefore, the field of non-destructive testing has been developed. Depending on the inspection task, different methods are available:

- visual inspection (VT)

- dye penetrant testing (PT)

- eddy current testing (ET)

- thermographic testing (TT)

- magnetic particle inspection (MT)

- ultrasonic testing (UT)

The ultrasonic method is suitable for inspecting components in depth. The method can be used to completely “x-ray” a wide range of materials. For this purpose, a measuring head with an ultrasonic transmitter and receiver is placed on the test part. The ultrasound generated in the probe is transported into the test part through a coupling medium, which, depending on the material, can be oil (metal) or hydrogel (composites), for example. Good coupling is essential for effective testing.

The ultrasound penetrates the specimen and echoes of the ultrasonic waves are generated by reflections from the back wall. Defects, such as cracks or inclusions, cause additional or premature reflection of the ultrasound. These are detected in the probe. The type and size of the reflections allow conclusions to be drawn as to where the anomaly found is located in the specimen and its dimensions. The manufacturing of ultrasonic probes is very complex. In addition, closed systems are required due to the coupling medium. Furthermore, the coupling medium must be as free as possible from impurities and bubbles, as these interfere with the ultrasound’s sound path and act like a material defect.

The current state

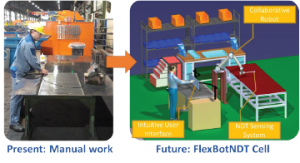

Ultrasonic testing is an essential part of quality control in the steel industry to reliably and accurately detect defects in the material. This is a critical task that can only be carried out by specialists who have been trained for many years. Currently, the inspection is performed manually with a probe that glides over the surface. This inspection is difficult to perform, especially for large-area components.

The project team consisting of Awesome Technologies, JOANNEUM RESEARCH ROBOTICS, Ondosense, LMS, and Voestalpin, is looking for a human-centered solution to bring quality control to the next level in the FlexBotNDT project, which is funded by EIT Manufacturing. The project idea behind it is to develop a combination of non-destructive testing equipment and collaborative robots that will relieve operators from monotonous scanning work and allow them to focus on important data analysis. This project is interesting for potential customers in the steel, aerospace, and aeronautics industries, both medium-sized companies, and large corporations.

Figure 1: Future Cell

Information about the project partners

Awesome Technologies takes care of the sales and marketing tasks, as well as the final integration into companies.

LMS, based in Greece, is managing the project and developing the user interface (UI) and controlling software (UR).

Ondosene has developed an innovative 3D radar sensor for collision avoidance, which works reliably even in the most difficult environments and enables privacy-compliant detection of human presence, eliminating the need for robot cages and allowing human-robot interaction to take place.

Joanneum Research Robotics is developing an end effector that can then be used to attach the probe to the cobot.

Voestalpin is the use-case donor and tests the final developed product and the quality of the sheet metal and steel beams.

The whole project is funded by EIT Manufacturing.

Milestones currently achieved

- The robot system is available for marketing by the store owner.

- Robot system

- Perception/vision system

- NDT ultrasonic system

- Safety concept and peripheral systems

- Programming and human-robot interaction system

Quick Overview

Project name: FlexBotNDT (Flexible non-destructive testing using collaborative robots)

Start date: 01 January 2022

End date: 31 December 2022

Contact persons/ project sponsors (with logo): Ondosense, Joanneum, Voestalpin, Awesome, LMS, EIT Manufacturing

Address:

Initial Situation: Ultrasonic testing is an essential part of quality inspection in the steel industry to reliably and accurately detect and visualize defects in the material. However, it is a critical task and the people who perform the testing are usually highly qualified experts. As a result, these people are hard to find, and often ultrasonic testing is a bottleneck on the shop floor. During the actual inspection process, the UT expert uses only a fraction of his time, namely for interpreting the results and analyzing the detected anomalies. Moving the probe over the surface and logging and documenting the results is the biggest time commitment.

Brief Description: With this project, we want to focus on the expertise and value of the human in the loop and relieve the experts from the monotonous and tedious work of moving the probe over the surface by using collaborative robots for this task. Moreover, the measurement results should be logged automatically and the user can fully concentrate on interpreting and approving the detected anomalies.

Objectives: Relieve the operator from monotonous scanning work – he can concentrate on data evaluation.

Overall objective: Human-machine cooperation for socially sustainable manufacturing on the basis of flexible NDT